Bolin Environmental Protection Technology

Focus on the research, development and sales of environmental protection equipment

Nantong Bolin Environmental Protection Technology Co., Ltd., established in April 2019, covers an area of 19 mu, with a factory area of 7500 square meters, a 4-story office building with a total area of 2400 square meters, a loading and unloading area of 25000 square meters, and a registered capital of 30 million yuan. It is a company engaged in the research, development, production and sales of environmental protection equipment. Mainly engaged in the research and development, transfer, consultation and service of technologies in the field of environmental protection; sales of steel, metal materials, hardware and electrical appliances, building materials and decoration materials.

Nantong Bolin Environmental Protection Technology Co., Ltd. is located in the Yangtze River Delta, a coastal open city - Nantong, with the Xinchang Railway, Ningqi Railway, National Highway 204 and the coastal expressway running through the whole territory, with convenient transportation. The company's production base is located in Rugao Industrial Park, an integrated industrial company integrating research, production, sales and service. There are currently 110 employees, including 12 engineering and technical personnel. Since its establishment, the company has always adhered to the principle of technology-driven, talent-based, competition-driven, user-service-oriented, occupying the market with new products, consolidating the market with high quality, and expanding the market with flexible operation.

Corporate Culture

Technological innovation is the foundation of the enterprise

Meeting customer needs is our goal

Corporate Goals

We are committed to becoming a global quality environmental protection equipment service provider, providing high-quality and high-precision steel structure needs to global customers through continuous innovation and technological progress.

Corporate Philosophy

We uphold the spirit of craftsmanship, devoting our hearts to every product, pursuing quality and details, and ensuring that every product meets the standards.

Corporate Values

We value teamwork and communication, advocating the spirit of "working together", facing challenges and difficulties together, and achieving common goals.

Corporate Responsibility

We are committed to the quality of our products, ensuring that every product has undergone rigorous testing and testing to meet customer requirements and expectations.

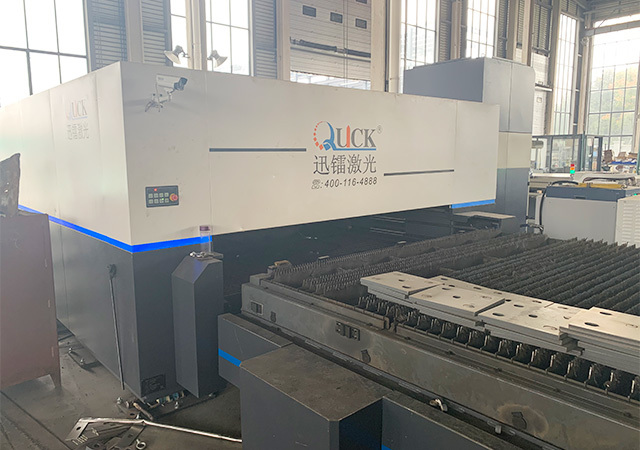

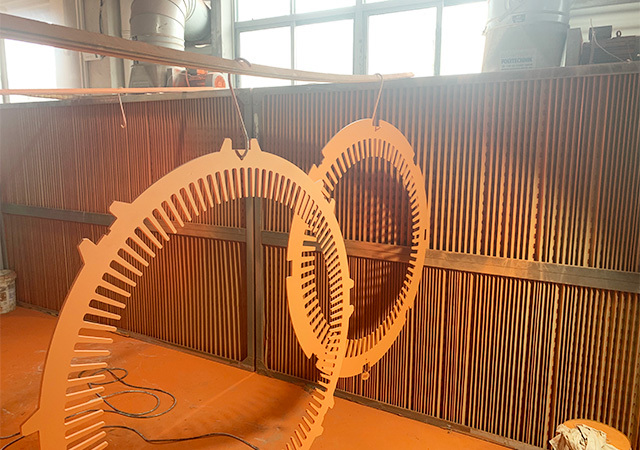

Workshop Introduction

Tel:86-13862750676

Email:ntjh87273099@163.com

Address:218 Chuangye Avenue, Rugao City, Jiangsu Province

Scan QR Code Mobile Version